Differenze tra le versioni di "Lever filler/en"

(Creata pagina con "Another noteworthy variant of the system is the one of Carter, derived from a patent ({{Cite patent|US|1209978}}) of the De Witt-La France, which has a sort of "leash"...") |

|||

| Riga 17: | Riga 17: | ||

The [[Conklin]] with the [[Endura]] introduced a version in which only half of the lever being lifted was exposed externally, reducing the size of the slit on the barrel. Moreover, the mechanism used by [[Conklin]], like that one of [[Eversharp]], did not use a ''spring bar'', but a pressure bar was stuck directly to the lever by means of two small hooks inside it, which went to fit into a special hook on the bar. | The [[Conklin]] with the [[Endura]] introduced a version in which only half of the lever being lifted was exposed externally, reducing the size of the slit on the barrel. Moreover, the mechanism used by [[Conklin]], like that one of [[Eversharp]], did not use a ''spring bar'', but a pressure bar was stuck directly to the lever by means of two small hooks inside it, which went to fit into a special hook on the bar. | ||

| − | + | Another noteworthy variant of the system is the one of [[Carter]], derived from a patent ({{Cite patent|US|1209978}}) of the [[De Witt-La France]], which has a sort of "leash" attached to the lever that prevents it from tipping over once it has reached the vertical position, in order to avoid damage to the pen and the system. | |

Infine una particolare versione di riempimento a levetta è quello della [[Skyline]] della [[Eversharp]], che potrebbe essere classificato anche fra i [[Caricamento#Caricamento a sfiatatoio|caricamenti a sfiatatoio]]. In tal caso infatti all'interno del serbatoio in gomma si ha uno sfiatatoio, e la ''[[spring bar]]'' è molto corta e volta a comprimere soltanto la parte finale del sacchetto. La penna viene caricata ripetendo più volte l'azione di pressione con la levetta, usando il principio classico dello sfiatatoio. Analogo a questo, anche se realizzato in maniera completamente diversa, è l'''[[Ink-Vue]]'' della [[Waterman]].<noinclude> | Infine una particolare versione di riempimento a levetta è quello della [[Skyline]] della [[Eversharp]], che potrebbe essere classificato anche fra i [[Caricamento#Caricamento a sfiatatoio|caricamenti a sfiatatoio]]. In tal caso infatti all'interno del serbatoio in gomma si ha uno sfiatatoio, e la ''[[spring bar]]'' è molto corta e volta a comprimere soltanto la parte finale del sacchetto. La penna viene caricata ripetendo più volte l'azione di pressione con la levetta, usando il principio classico dello sfiatatoio. Analogo a questo, anche se realizzato in maniera completamente diversa, è l'''[[Ink-Vue]]'' della [[Waterman]].<noinclude> | ||

Versione delle 00:14, 21 ago 2019

The lever filler is probably the filling system most common among vintage pens (and has also been used, as a form of revival, by some modern manufacturers). Introduced massively to the market in 1912 by Sheaffer, who has always proclaimed its invention, it has been produced in countless variations and versions, many of which, often technically inferior, have been created only to circumvent the patent (nº US-896861) that covered the invention of Walter Sheaffer that originated in 1908.

In fact, the ancestry of Sheaffer is seriously under discussion; in fact, there are previous versions of this loading system, a Swedish Johansson patent from 1898 and an American Barnes patent (nº US-726495) from 1903, the presence of which has allowed other companies, such as Waterman, to use variants of the same system. However, the success of the system and its enormous diffusion can be attributed to the massive investments of Sheaffer.

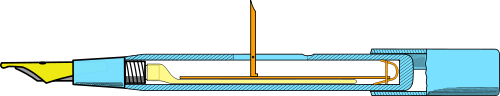

In the case of the Sheaffer patent the mechanism involves the compression of the sac using a lever that press on an elastic metal bar (the so-called spring bar) shaped like a "J", this one is inserted in the body of the pen with the curved part towards the bottom so as to make to adhere the straight part on the barrel of the pen, in correspondence of the lever. In many cases the pressure on the sac is not directly exerted by the spring bar that is hooked to a pressure bar which is the one that is pressed against the bag.

In the rest position the lever is placed horizontally in a slot in the side of the pen body. In the original version of Sheaffer it was held in place by a thin metal pin that crossed it centrally, inserted directly into the shaft of the pen, which was drilled for the occasion. Lifting the lever from one side the other side pushes down the pressure bar, which thus compresses the sac.

As mentioned above, there are several different versions of this mechanism. For example, Waterman, in order to circumvent Sheaffer's patent, introduced, based on Barnes's patent, a lever pivoted directly inside a metal cage that contained the entire mechanism. This in turn was fixed with fins to the pen, using as housing a special slit created in the barrel side.

A more efficient system, later used by other producers including Sheaffer itself, requires the lever to be held in place by a metal ring through it. This is inserted inside the pen and maintained in position by means of a special groove, made internally on the barrel in correspondence with the lateral opening from which the lever itself is housed. This system has the considerable advantage of greater mechanical strength, since it does not require drilling holes for the pin in the material of the barrel, which in ebonite pens was often quite fragile.

Other variations of the system concern the way in which the lever exerts pressure on the sac: for example the Eversharp did not use a flexible bar but a flat bar with the sides folded like a "U", anchored on a hook on the bottom of the pen. The lever was equipped on the external end with two tips that went to fit in the rail obtained from the folding of the bar, so as to raise it to the rest position after filling, furthermore to keep the lever locked in the rest position, it was equipped with small protrusions that went to fit into special recesses created in the housing slit.

The Conklin with the Endura introduced a version in which only half of the lever being lifted was exposed externally, reducing the size of the slit on the barrel. Moreover, the mechanism used by Conklin, like that one of Eversharp, did not use a spring bar, but a pressure bar was stuck directly to the lever by means of two small hooks inside it, which went to fit into a special hook on the bar.

Another noteworthy variant of the system is the one of Carter, derived from a patent (nº US-1209978) of the De Witt-La France, which has a sort of "leash" attached to the lever that prevents it from tipping over once it has reached the vertical position, in order to avoid damage to the pen and the system.

Infine una particolare versione di riempimento a levetta è quello della Skyline della Eversharp, che potrebbe essere classificato anche fra i caricamenti a sfiatatoio. In tal caso infatti all'interno del serbatoio in gomma si ha uno sfiatatoio, e la spring bar è molto corta e volta a comprimere soltanto la parte finale del sacchetto. La penna viene caricata ripetendo più volte l'azione di pressione con la levetta, usando il principio classico dello sfiatatoio. Analogo a questo, anche se realizzato in maniera completamente diversa, è l'Ink-Vue della Waterman.

Brevetti correlati

- Brevetto n° US-726495, del 1903-04-28, richiesto il 1902-11-22, di John S. Barnes, Waterman. Caricamento a levetta.

- Brevetto n° US-896861, del 1908-08-25, richiesto il 1908-03-02, di Walter A. Sheaffer, W. A. Sheaffer Pen Company. Caricamento a levetta.

- Brevetto n° US-1005387, del 1911-10-10, richiesto il 1911-05-04, di Ruel W. Whitney, Whitney-Richards. Caricamento a levetta.

- Brevetto n° US-1046660, del 1912-12-10, richiesto il 1912-03-21, di Walter A. Sheaffer, W. A. Sheaffer Pen Company. Aggancio barra di pressione.

- Brevetto n° US-1114052, del 1914-10-20, richiesto il 1912-11-18, di Walter A. Sheaffer, W. A. Sheaffer Pen Company. Caricamento a levetta.

- Brevetto n° US-1118240, del 1914-11-24, richiesto il 1913-02-19, di Walter A. Sheaffer, W. A. Sheaffer Pen Company. Caricamento a levetta.

- Brevetto n° US-1124750, del 1915-01-12, richiesto il 1914-02-27, di Joseph A. Kracker, Kraker. Caricamento a levetta.

- Brevetto n° US-1152509, del 1915-09-07, richiesto il 1914-11-03, di John A. Holland, John Holland Pen Company. Caricamento a levetta snodabile.

- Brevetto n° US-1156748, del 1915-10-12, richiesto il 1915-03-19, di Edwin F. Britten, Waterman. Caricamento a levetta.

- Brevetto n° GB-191505790, del 1915-11-18, richiesto il 1914-08-17, di William I. Ferris, Edwin F. Britten, Waterman. Caricamento a levetta.

- Brevetto n° US-1170825, del 1916-02-08, richiesto il 1914-11-30, di Joseph A. Kracker, Kraker. Caricamento a levetta.

- Brevetto n° US-1176529, del 1916-03-21, richiesto il 1915-07-19, di William I. Ferris, Waterman. Caricamento a levetta.

- Brevetto n° US-1180946, del 1916-04-25, richiesto il 1915-02-02, di Felix Riesenberg, Waterman. Caricamento a levetta.

- Brevetto n° FR-480426, del 1916-08-03, richiesto il 1915-03-19, di Edwin F. Britten, Waterman. Caricamento a levetta.

- Brevetto n° US-1194510, del 1916-08-15, richiesto il 1914-02-25, di George M. Kracker, Kraker. Caricamento a levetta.

- Brevetto n° US-1195709, del 1916-08-22, richiesto il 1916-01-20, di Lucifer J. Most, Unbranded. Caricamento a levetta.

- Brevetto n° US-1197360, del 1916-09-05, richiesto il 1914-08-17, di William I. Ferris, Edwin F. Britten, Waterman. Caricamento a levetta.

- Brevetto n° US-1199993, del 1916-10-03, richiesto il 1914-12-23, di George M. Kracker, Kraker. Caricamento a levetta.

- Brevetto n° US-1205847, del 1916-11-21, richiesto il 1916-09-30, di Claes W. Boman, Eagle. Caricamento a levetta.

- Brevetto n° US-1209978, del 1916-12-26, richiesto il 1916-01-01, di David J. La France, Carter's Ink Company, Boston Pen. Caricamento a levetta.

- Brevetto n° US-1228177, del 1917-05-29, richiesto il 1915-07-19, di Edwin F. Britten, Waterman. Caricamento a levetta.

- Brevetto n° US-1238657, del 1917-08-28, richiesto il 1917-02-17, di Marx Finstone, Eclipse. Caricamento a levetta.

- Brevetto n° US-1242323, del 1917-10-09, richiesto il 1914-04-09, di Harvey G. Craig, Kraker. Caricamento a levetta.

- Brevetto n° US-1247037, del 1917-11-20, richiesto il 1916-10-25, di Henry J. Upton, Vaughn-Upton. Caricamento a levetta.

- Brevetto n° US-1249501, del 1917-12-11, richiesto il 1916-06-27, di Felix Riesenberg, Swan. Sistema di caricamento.

- Brevetto n° US-1251421, del 1917-12-25, richiesto il 1915-11-29, di Felix Riesenberg, Swan. Sistema di caricamento.

- Brevetto n° US-1258458, del 1918-03-05, richiesto il 1917-10-29, di Hans P. Ravn, Welty. Caricamento a levetta.

- Brevetto n° US-1260165, del 1918-03-19, richiesto il 1916-10-27, di William F. Duryea, Salz. Caricamento a levetta.

- Brevetto n° US-1261481, del 1918-04-02, richiesto il 1917-12-18, di George F. Brandt, Moore Pen Company. Caricamento a levetta.

- Brevetto n° US-1263260, del 1918-04-16, richiesto il 1918-03-11, di Rudolph Wm. Lotz, Kraker. Caricamento a levetta.

- Brevetto n° US-1263261, del 1918-04-16, richiesto il 1918-03-11, di Rudolph Wm. Lotz, Kraker. Caricamento a levetta.

- Brevetto n° US-1263808, del 1918-04-23, richiesto il 1918-01-02, di Jacob Salz, Salz. Caricamento a levetta.

- Brevetto n° US-1267288, del 1918-05-21, richiesto il 1916-10-19, di Tagiro Tanimura, Swan. Sistema di caricamento.

- Brevetto n° US-RE14474, del 1918-05-21, richiesto il 1918-03-28, di Felix Riesenberg, Swan. Sistema di caricamento.

- Brevetto n° US-1288819, del 1918-12-24, richiesto il 1918-04-19, di George F. Brandt, Moore Pen Company. Caricamento a levetta.

- Brevetto n° US-1290365, del 1919-01-07, richiesto il 1918-07-05, di Ferdinand Scheiblecker, Salz. Caricamento a levetta.

- Brevetto n° US-1292736, del 1919-01-28, richiesto il 1916-01-20, di August G. Elser, C. E. Barret & Company. Caricamento a levetta.

- Brevetto n° US-1299642, del 1919-04-08, richiesto il 1918-03-23, di William A. Welty, Hans P. Ravn, Welty. Caricamento a levetta.

- Brevetto n° US-1304739, del 1919-05-27, richiesto il 1919-01-02, di Herbert L. Carman, Swan. Caricamento a levetta.

- Brevetto n° US-1312681, del 1919-06-24, richiesto il 1917-12-22, di William L. Chapman, A. A. Waterman. Caricamento a levetta.

- Brevetto n° GB-118118, del 1919-09-08, richiesto il 1916-06-27, di Felix Riesenberg, Swan. Sistema di caricamento.

- Brevetto n° US-1321188, del 1919-11-11, richiesto il 1919-05-17, di Homer Catucci, Swan. Caricamento a levetta.

- Brevetto n° US-1325844, del 1919-12-23, richiesto il 1917-06-25, di Hugo S. Hasselquist, Wahl Eversharp. Caricamento a levetta.

- Brevetto n° US-1328215, del 1920-01-13, richiesto il 1918-12-21, di De Witt C. Van Valer, A. A. Waterman. Caricamento a levetta.

- Brevetto n° US-1351574, del 1920-08-31, richiesto il 1917-04-02, di Charles R. Keeran, Wahl Eversharp. Caricamento a levetta.

- Brevetto n° US-1351591, del 1920-08-31, richiesto il 1917-08-27, di John C. Wahl, Wahl Eversharp. Caricamento a levetta.

- Brevetto n° GB-151753, del 1920-10-07, richiesto il 1919-07-09, di George Davies, Wyvern Fountain Pen Company. Caricamento a levetta.

- Brevetto n° US-1365754, del 1921-01-18, richiesto il 1918-01-05, di John C. Wahl, Wahl Eversharp. Caricamento a levetta.

- Brevetto n° US-1367255, del 1921-02-01, richiesto il 1917-03-28, di Hugo S. Hasselquist, Wahl Eversharp. Caricamento a levetta.

- Brevetto n° US-1379890, del 1921-05-31, richiesto il 1920-06-30, di Paul E. Wirt, Wirt. Caricamento a levetta.

- Brevetto n° US-1391430, del 1921-09-20, richiesto il 1917-06-25, di Milton C. Taylor, Wahl Eversharp. Caricamento a levetta.

- Brevetto n° US-1407552, del 1922-02-21, richiesto il 1920-02-11, di Rudolph Wm. Lotz, Kraker. Caricamento a levetta.

- Brevetto n° US-1435446, del 1922-11-14, richiesto il 1921-01-13, di David W. Beaumel, Beaumel. Caricamento a levetta.

- Brevetto n° US-1446524, del 1923-02-27, richiesto il 1922-05-01, di Ivan D. Tefft, Wahl Eversharp. Levetta Wahl Engine Turned.

- Brevetto n° US-1452653, del 1923-04-24, richiesto il 1920-06-11, di Arthur F. Poole, George B. Vernier, Wahl Eversharp. Caricamento a levetta.

- Brevetto n° US-1472963, del 1923-11-06, richiesto il 1922-01-06, di William P. De Witt, De Witt-La France. Caricamento a levetta.

- Brevetto n° US-1475953, del 1923-12-04, richiesto il 1923-02-10, di David Klein, Eclipse. Caricamento a levetta.

- Brevetto n° FR-568834, del 1924-04-02, richiesto il 1922-07-19, De La Rue - Onoto. Caricamento a levetta.

- Brevetto n° US-1490686, del 1924-04-15, richiesto il 1921-10-27, di John C. Wahl, Wahl Eversharp. Caricamento a levetta.

- Brevetto n° US-1490735, del 1924-04-15, richiesto il 1923-03-22, di William P. De Witt, De Witt-La France. Caricamento a levetta.

- Brevetto n° CA-243009, del 1924-09-16, richiesto il 1922-07-19, di Harry Ross, De La Rue - Onoto. Caricamento a levetta.

- Brevetto n° GB-228672, del 1925-02-12, richiesto il 1923-12-11, di William Livsey, Lang - Curzon - Summit. Caricamento a levetta.

- Brevetto n° GB-232519, del 1925-04-23, richiesto il 1924-12-08, di William Livsey, Stephens, Lang - Curzon - Summit. Caricamento a levetta.

- Brevetto n° US-1537226, del 1925-05-12, richiesto il 1922-01-21, di William P. De Witt, De Witt-La France. Caricamento a levetta.

- Brevetto n° FR-589169, del 1925-05-25, richiesto il 1924-06-02, De La Rue - Onoto. Caricamento a levetta.

- Brevetto n° US-1540416, del 1925-06-02, richiesto il 1924-07-23, di Ryosuke Namiki, Pilot. Caricamento a levetta.

- Brevetto n° GB-235447, del 1925-06-18, richiesto il 1924-10-22, di George Frank Smith, Conway Stewart. Caricamento a levetta.

- Brevetto n° US-RE16145, del 1925-08-18, richiesto il 1918-01-05, di John C. Wahl, Wahl Eversharp. Caricamento a levetta.

- Brevetto n° GB-239274, del 1925-09-02, richiesto il 1924-06-02, di Henry J. Dixon, De La Rue - Onoto. Caricamento a levetta.

- Brevetto n° US-1561590, del 1925-11-17, richiesto il 1924-02-25, di Andreas Bienenstein, Conklin Pen Manufacturing Co.. Caricamento a levetta.

- Brevetto n° US-1569783, del 1926-01-12, richiesto il 1922-09-16, di Eric G. Pearson, Eagle. Caricamento a levetta.

- Brevetto n° US-1574266, del 1926-02-23, richiesto il 1921-11-07, di John C. Wahl, Wahl Eversharp. Caricamento a levetta.

- Brevetto n° US-RE16349, del 1926-05-11, richiesto il 1924-02-24, di Ivan D. Tefft, Wahl Eversharp. Levetta Wahl Engine Turned.

- Brevetto n° US-1585805, del 1926-05-25, richiesto il 1922-07-15, di John C. Wahl, Ivan D. Tefft, Wahl Eversharp. Levetta Wahl Engine Turned.

- Brevetto n° US-1613804, del 1927-01-11, richiesto il 1920-06-11, di Arthur F. Poole, Wahl Eversharp. Caricamento a levetta.

- Brevetto n° US-1624190, del 1927-04-12, richiesto il 1922-04-10, di Ivan D. Tefft, Wahl Eversharp. Levetta Wahl Engine Turned.

- Brevetto n° US-1624194, del 1927-04-12, richiesto il 1922-07-15, di John C. Wahl, Wahl Eversharp. Caricamento a levetta.

- Brevetto n° GB-289969, del 1928-05-07, richiesto il 1927-02-07, di Henry J. Dixon, De La Rue - Onoto. Caricamento a levetta.

- Brevetto n° US-1669714, del 1928-05-15, richiesto il 1926-11-08, di David J. La France, Carter's Ink Company. Caricamento a levetta.

- Brevetto n° FR-33407E, del 1928-09-28, richiesto il 1927-02-07, De La Rue - Onoto. Caricamento a levetta.

- Brevetto n° GB-323129, del 1929-12-24, richiesto il 1929-01-18, di Eric Ernest Samuel Wade, Lang - Curzon - Summit. Caricamento a levetta.

- Brevetto n° US-1852094, del 1932-04-05, richiesto il 1930-10-20, di Herman K. Stempel, W. A. Sheaffer Pen Company. Caricamento a levetta.

- Brevetto n° US-2241850, del 1941-05-13, richiesto il 1939-11-27, di William J. Gillet, Victor C. Sharp, W. A. Sheaffer Pen Company. Caricamento a levetta.

- Brevetto n° US-2325069, del 1943-07-27, richiesto il 1942-03-02, di Fred P. Moore, Wahl Eversharp. Caricamento a levetta.

- Brevetto n° GB-575341, del 1946-02-13, richiesto il 1944-03-10, di Edward Stephen Sears, Swan. Caricamento a levetta.

- Brevetto n° US-2398521, del 1946-04-16, richiesto il 1944-01-20, di George D. Cloutier, Wahl Eversharp. Alimentatore e caricamento Fifth Avenue.

- Brevetto n° FR-1037142, del 1953-09-15, richiesto il 1951-05-16, Stylomine. Caricamento a levetta.

- Brevetto n° US-2807237, del 1957-09-24, richiesto il 1953-06-15, di David Kahn, Morris D. Levy, Wearever. Caricamento a levetta.