Differenze tra le versioni di "Match-stick filler/en"

(Creata pagina con "The problems of this mechanism were mostly related to providing adequate positioning to the ''pressure bar'' (it was usually glued). The system was not particularly sturdy...") |

|||

| (2 versioni intermedie di 2 utenti non mostrate) | |||

| Riga 1: | Riga 1: | ||

| − | The ''match-stick filler'' system is one of many systems designed at the beginning of the century to try to automate the fountain pen ink filling. In this case it was a matter of compressing the rubber tank through the use of a match (or a toothpick or other similar tool) that went to press, through a hole made on the shaft of the pen, on the compression bar. | + | <noinclude>{{ReferBox|Filling systems}}</noinclude>The ''match-stick filler'' system is one of many systems designed at the beginning of the century to try to automate the fountain pen ink filling. In this case it was a matter of compressing the rubber tank through the use of a match (or a toothpick or other similar tool) that went to press, through a hole made on the shaft of the pen, on the compression bar. |

[[Image:MatchStickFillerSchema.svg|center|500px|Diagram of a pen with ''match-stick filler'']] | [[Image:MatchStickFillerSchema.svg|center|500px|Diagram of a pen with ''match-stick filler'']] | ||

| Riga 5: | Riga 5: | ||

The problems of this mechanism were mostly related to providing adequate positioning to the ''[[pressure bar]]'' (it was usually glued). The system was not particularly sturdy, nor elegant, and it assumed however the possession of a match, without which it turned out useless. To this problem some producers had obviated making the [[clasp]] dismountable and usable to the place of the match, or creating an opportune protuberance on the head of the cap or using some alternative form in order to furnish an adequate partridge. | The problems of this mechanism were mostly related to providing adequate positioning to the ''[[pressure bar]]'' (it was usually glued). The system was not particularly sturdy, nor elegant, and it assumed however the possession of a match, without which it turned out useless. To this problem some producers had obviated making the [[clasp]] dismountable and usable to the place of the match, or creating an opportune protuberance on the head of the cap or using some alternative form in order to furnish an adequate partridge. | ||

| − | + | The system is therefore quite primitive since no one had found a solution to its most important problem, that in case of breakage of the inner rubber bag, the ink could escape from the hole on the body of the pen with the imaginable unpleasant consequences.<noinclude> | |

| − | == | + | ==Related Patents== |

| − | {{ | + | {{ListsPatentsFeature|Match-stick filler}} |

| − | + | [[Category:Translated Pages]] | |

</noinclude> | </noinclude> | ||

Versione attuale delle 20:43, 27 ago 2019

| Filling systems |

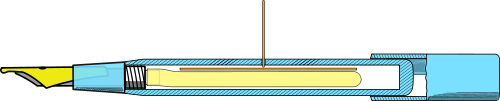

The match-stick filler system is one of many systems designed at the beginning of the century to try to automate the fountain pen ink filling. In this case it was a matter of compressing the rubber tank through the use of a match (or a toothpick or other similar tool) that went to press, through a hole made on the shaft of the pen, on the compression bar.

The problems of this mechanism were mostly related to providing adequate positioning to the pressure bar (it was usually glued). The system was not particularly sturdy, nor elegant, and it assumed however the possession of a match, without which it turned out useless. To this problem some producers had obviated making the clasp dismountable and usable to the place of the match, or creating an opportune protuberance on the head of the cap or using some alternative form in order to furnish an adequate partridge.

The system is therefore quite primitive since no one had found a solution to its most important problem, that in case of breakage of the inner rubber bag, the ink could escape from the hole on the body of the pen with the imaginable unpleasant consequences.

Related Patents

- Patent n° US-766560, of 1904-08-02, requested on 1904-05-16, of Otto E. Weidlich, Weidlich. Fountain-pen.

- Patent n° US-827022, of 1906-07-24, requested on 1905-07-22, of David B. Kaufmann, Unbranded. Fountain-pen.

- Patent n° US-1049465, of 1913-01-07, requested on 1912-01-18, of William F. Duryea, Salz. Self-filling pen.

- Patent n° US-1198994, of 1916-09-19, requested on 1916-06-29, of Claes W. Boman, Eagle. Fountain-pen.

- Patent n° US-1475954, of 1923-12-04, requested on 1923-02-10, of David Klein, Eclipse. Self-filling fountain pen.